WORKNC Opens Doors For Collet Amblard

WORKNC has opened the door to new markets for a manufacturer of precision machine components and the production of pre-assembled units.

"WORKNC’s functionality means we can always find a solution to machining any type of part. No geometry is too complex for us now.“

Eric Moinet, Project Manager

Eric Moinet, Project Manager for Société Collet Amblard, based at Grenoble in France, says many components such as pump housings, volutes and impellers that they produce for the nuclear and hydraulic sectors, were impossible to machine before they installed WORKNC from Vero Software, in 2009.

“Our previous CAM system was no longer suitable to meet customers’ requirements or the needs of new markets. I’d used WORKNC at another company and was impressed by how easy it was to program, and by the reliable toolpaths it created for cutting metal on the machine tools.”

Collet Amblard is part of the Hephaistos Group, and was founded in 1928. Now operating out of a 2,400 square metre factory, based in the city of Veurey Voroize with 19 employees, the company produces custom-made parts or complete, pre-assembled and tested units for the nuclear energy industry. Most have complex geometries and are machined from exotic or hard materials such as stainless steel and specialised steel alloys. In addition, they have expertise of metalworking, welding, through the company, BETRI – which also belongs to the Group – and inspection, using a tridimensional measuring machine and PC DMIS license from Hexagon Manufacturing Intelligence.

Around 50 per cent of their work goes to nuclear customers, with blades and impellers making up 30 per cent, for the hydraulic industry, with the remaining 20 per cent for plastics and new energies. Their three main customers are General Electrical, Air Liquide and Areva.

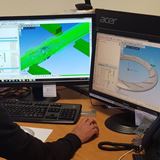

WORKNC drives five vertical machining centres – two Mazak VTC 300 C, a CB Ferrari 5 axis centre, and two 5-axis Sackman mills. “Thanks to WORKNC I can generate the post processors for all our 3-axis and 3+2 axis jobs, allowing greater reactivity and independence,” he says.

When beginning a new project, he firstly recovers the CAD data of the customer’s part, and determines the different milling and turning operations using 3D shopfloor programming methods with WORKNC. The software is used when the component’s shape and complexity does not allow the operator to machine it directly. He then defines a CAM process using WORKNC for roughing, re-roughing, finishing and optimisation.

“Programming extremely quick and easy, and the toolpaths transmitted to the required machine through the network. Once machining is finished, the part is inspected on the tridimensional measuring machine using Hexagon Manufacturing Intelligence’s PC-DMIS software.”

He finds a number of items of functionality to be particularly important, such as radii, drafts and undercuts and section CAD analysis, especially for volutes. For the minimum raw dimensioning he uses the Bounding Box function.

Moving onto CAM, the roughing and re-roughing toolpaths are optimised for reduced air cutting time, with localised retracts and corner smoothing, and also for automatic detection and machining flat surfaces.

“The Rest Material Display function lets me rapidly evaluate the different amounts of rest material left on the model, according to user-defined colour ranges. This single function saves time and considerably improves the roughing and semi-finishing stages. And the Undercut machining toolpath uses lollipop cutters for easy detection and 3-axis machining of undercut areas.”

With the new 2017 R1 edition WORKNC, he is aiming to test the new Shop Floor Editor, to give operators more freedom and flexibility. “This effectively makes it easier for operators to visualise, simulate and control toolpaths before running them on the CNC machines. They can modify the cutting parameters directly on the machine and rerun the postprocessor, but only within the machining environment predefined by the programmer.”

He says overall, WORKNC has reduced 3D programming times by a factor of four – down to half an hour instead of a full morning – and is used in fabricating all parts based on the 3D geometry file.

“Operators can easily modify the toolpath trajectories in the graphic display by deleting specific zones or passes according to the areas to be machined, while the collision management module maintaining the same reliability – something which is not always possible with other CAM applications.”

Eric Moinet is responsible for evaluating the complexity of the geometry and the different machining methods – turning or milling – required to produce the parts, and says he is confident that even though every order is made to measure, each tool is different, and requires individual project management, when every component comes off the machine tool, they will all be perfect.

“WORKNC’s functionality means we can always find a solution to machining any type of part. No geometry is too complex for us now.”

About the company

Name : Collet Amblard

Business: Manufacturer of precision machine components and pre-assembled units.

Benefits

-

Reliable toolpaths for cutting metal.

-

Greater reactivity and independence.

-

Extremely quick and easy programming.

-

Easier for operators to visualise, simulate and control toolpaths.

-

Reduced 3D programming times down to half an hour rather than a full morning (a reduction factor of 4).

-

No geometry too complex to machine.

Comments

“This single function [Rest Material Display] saves time and considerably improves the roughing and semi-finishing stages.”

Eric Moinet, Project Manager